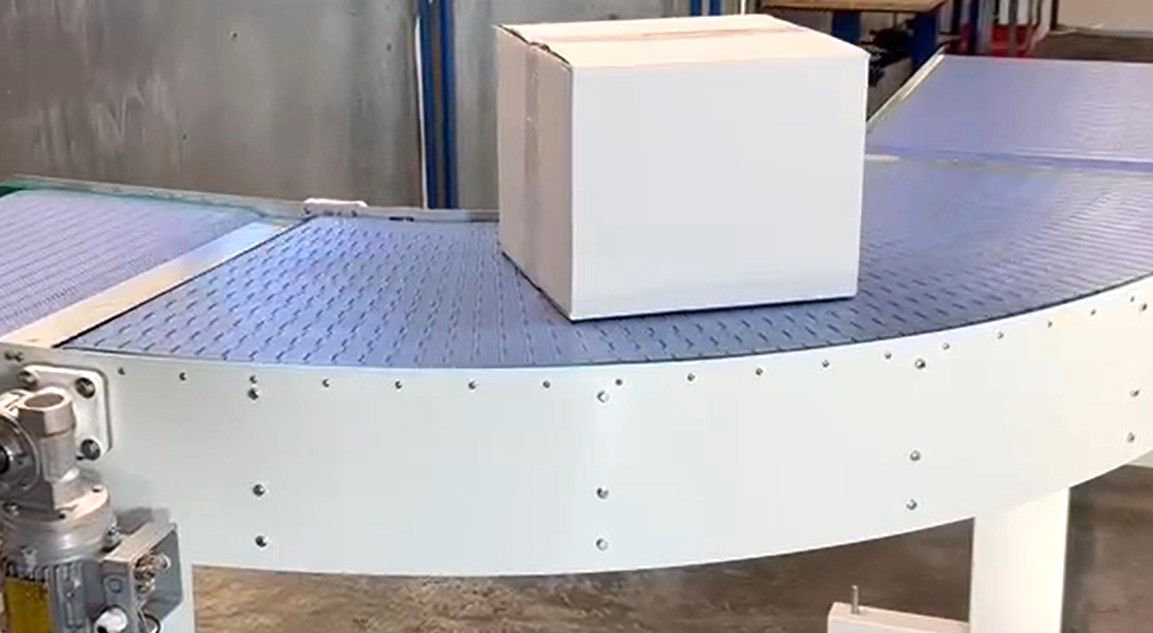

Curved conveyors with modular plastic belts

COMPACT DESIGN – IDEAL FOR TIGHT SPACES

No straight sections IN-OUT required Extremely small inner radius, even on wider curves.

SLIP-FREE DRIVE

The belt is driven by sprockets that ensure continuous, slip-free movement under all working conditions.

EXCELLENT PERFORMANCE

High operating speeds possible. Constant and perfect positioning of the products throughout the entire path. Silent running, fully compliant with noise regulatory standards

LONG SERVICE LIFE

Low maintenance, minimal downtime, and reduced operating costs Repairs are significantly faster than with traditional belt curves and can often be carried out even by non-expert personnel

Curve transport with no product damage

Standard angles: 45°, 90°, and 180° – Any angle from a minimum of 35° available on request

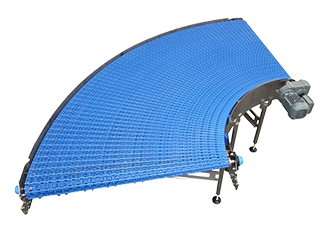

CURVED CONVEYOR WITH OPEN TOP BELT

HYGIENIC MWC

Hygienic design, ensuring in-depth and easy cleaning

Robust open top “finger safe” modular plastic belt designed for fingers protection according to EU standards. The open surface allows the passage of water, air, and debris, making cleaning and sanitization easier.

Belt in PA, suitable for direct food contact, blue color, with stainless steel rods.

Available in various internal radius combinations: 942, 767, and 600 mm, with a wide range of widths from 225 mm to 2000 mm

- Operating temperature range: from -40 °C to +120 °C

- Product contact temperature range: from -40 °C to +160 °C

Built with a sturdy structure in stainless or painted steel, the curved conveyor features an exceptionally hygienic design. Side openings can be optionally included to enhance cleaning and airflow access

Suitable to both heavy loads and high-speed transport

Its exceptional qualities make it ideal for food industry transport and suitable for numerous other industrial applications

Available upon request in metal-detectable material, ensuring maximum food safety

CURVED CONVEYOR WITH CLOSED TOP BELT

ZERO STOP ONDA

Efficient curved transport for all product types in industrial and food sectors

Featuring a sturdy modular plastic belt with a closed surface, these curves are suitable for handling all types of products, whether food or industrial

Standard belt in POM, certified for food contact, blue color, with PA or steel rods; Other materials are available depending on the application

Multiple belt widths available, from 200 mm up to 1800 mm, with a minimum internal radius of only 600 mm (e.g., 1800 mm width with 600 mm internal radius). Larger internal radii are also available depending on the belt width

- Operating temperature range: from -40 °C to +65 °C

- Product contact temperature range: from -40 °C to +80 °C

Curved conveyor’s structure made of stainless steel, painted steel, or scratch-resistant galvanized sheet metal

The curved belt is resistant to heavy loads and high-speed product transport

Side openings, available upon request, enable internal cleaning and airflow access

It effectively manages curved transport requirements in numerous production areas, including logistics, shrink-wrapping, food, canning, industrial goods, and packaging.