Modular Plastic Belts

We are official distributors of Eurobelt modular belts

Eurobelt belts are made from high-quality plastic modules, manufactured exclusively within the European Community and assembled into configurations with particularly robust structures. They can be produced in a wide range of widths and in any length multiple of the belt pitch, with a broad selection of flights, side guards, and other accessories.

100% TECHNICAL SUPPORT

Choosing the right type of belt and the most suitable material based on working conditions is essential to ensure maximum durability and efficiency over time. For this reason, we encourage you to contact us at the start of every new project so we can provide the best possible support.

For company technical departments, we offer 2D and 3D drawings in IGS and STP formats to facilitate faster and more precise design work.

URGENT DELIVERY SERVICE

For emergencies, i.e. sudden machine breakdowns, we offer an urgent delivery service for belts, components, and spare parts ( such as modules, rods, sprockets etc.). We ensure direct shipping from Eurobelt’s headquarters to the customer’s location via air transport, with an estimated delivery time of 2-3 working days.

Contact us for a cost evaluation of the service.

Key Industries for Modular Belt Applications

- Small pitch to facilitate the transfer of smaller products from one conveyor to the next

- Wide open area for optimal product cooling at oven outfeed

- Belts suitable for upright transport of biscuits

- Good heat resistance: Suitable for temperatures up to 100°C with standard materials; special materials available for higher temperatures.

- Belts for spirals: cooling, freezing

- Product packaging lines

- Small pitch for easier transfer of products

- Flat surfaces for greater stability of containers

- Active transfer for smooth 90° product redirection

- Outstanding belt capacity for pasteurization lines (for cans, wine, juices, etc.)

- Low-friction materials for all sliding and accumulation applications, reducing pressure on cans and PET bottles

- Optional free rollers on the belt for effective bundle accumulation

- Robust curved belt for handling bundles of cans, PET bottles, and clusters

- Bulk fruit and vegetable transport during processing

- Belts for handling jars and containers, both empty and full, with optional finger transfer for smoother product transition

- Excellent load capacity for belts used in pasteurization lines (for tinplate cans, glass jars, etc.), resistant up to 98–100°C

- Smooth container transfer at 90° at the pasteurizer entry and exit without complications

- Dedicated belts for palletizing and depalletizing of empty and full containers

- Belts designed for the tomato industry, covering the entire production cycle

- Low-friction belts to reduce pressure on jars and cans

- Systems designed for beef and pork processing, covering deboning, trimming and transport in cured meat and ham production facilities

- Engineered for optimal sanitization: non-absorbent to blood or liquids and compliant with all relevant current certifications

- Constructed with impact-resistant materials suitable for processing, deboning, and cutting directly on the belt, ensuring durability during bone handling and transport

- Conveyor belts with cleats designed for efficient removal of waste and bones, or for elevating various products, including minced meat

- Built with materials suitable for transporting frozen items such as meat blocks and hamburgers in meat processing plants

- Systems featuring belts tailored for spiral cooling and curved transport applications (e.g., hamburger lines)

- Belts for product weighing lines

- Belts configured for both straight and curved transport, enabling smooth handling of trays, cardboard boxes, and bags for packaging

- Transportation of fruits and vegetables along processing lines, including harvesting directly from the fields

- Conveyor belts with cleats designed to elevate products to higher levels

- Open-surface belts engineered for product washing, allowing optimal water flow and drainage

- Belts suitable for vegetable cooking processes (e.g., artichoke cookers)

- Specialized belts for freezing systems operating down to -40°C

- As well as conveyors for transporting packaged items such as salad bags, boxes, and trays

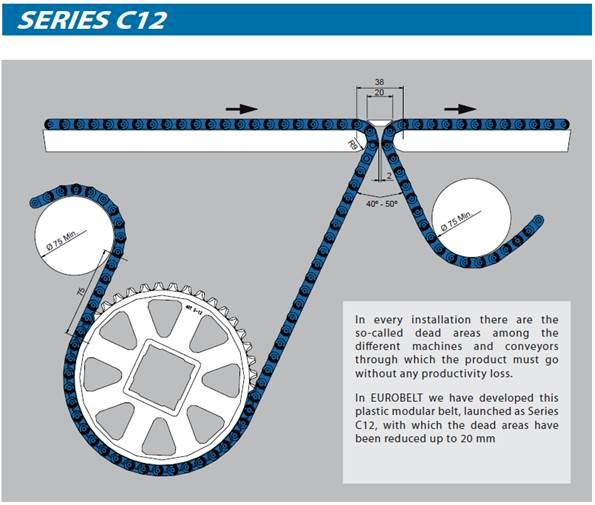

- Small pitch design to facilitate the transfer of smaller products from one belt to another

- Heat-resistant belts capable of withstanding extreme temperatures: over 100°C with standard materials and nearly 200°C with specialized materials

- Belts for spiral systems used in thermal treatment processes such as drying, cooling, and freezing

- Belts for fresh pasta forming machines (e.g., ravioli, tortellini)

- Conveyor systems for product packaging lines

- Transportation of fresh cheese molds throughout the hardening process (for cheeses destined for maturation, such as Pecorino and Grana)

- Movement of molds across production lines

- Lines dedicated to the transport of fresh and pre-packaged dairy products such as butter and soft cheeses

- Conveyor lines for mozzarella production, leading to final packaging

- Systems for transporting dairy product containers—such as yogurt—in single rows or grouped packs

- Hygiene and food safety significantly improved through the use of modular plastic conveyor belts

- Reduced cleaning times and lower sanitization costs

- Transport and handling of food and industrial products across all stages of packaging lines

- Parcel transportation within sorting systems for courier services and airport facilities

- Conveyor belts functioning as operator platforms in assembly lines, designed with antistatic properties to eliminate static charges

- Heavy-duty belts engineered for moving vehicles and large components along production lines

- Belts for tires transport in production systems

- Belts used in rubber processing and manufacturing operations

- Specialized belts for battery production lines, made with materials resistant to sulfuric acid